CNC machining parts sticking knife solution

CNC processing refers to the processing of parts using CNC machining tools, which have significant advantages compared to manual tools. For example, t

CNC processing refers to the processing of parts using CNC machining tools, which have significant advantages compared to manual tools. For example, t

The surface processing method of CNC machining workpieces depends primarily on the technical requirements of the surface. However, it should be noted

The material you choose for CNC machining will depend on the desired application and end product. Common materials used for CNC machining include alum

How Sheet Metal Gets Bent Sheet metal bending is done with a press brake, where a metal sheet is placed between two pieces of punch and die. The punch

Accuracy and precision are both highly important factors in machining, and both quality attributes are necessary for successful machining. To achieve

Contracting CNC machining services can be a great way to reduce production costs and improve product quality. In this article, we will explore some of

CNC Machining is a form of automated machining that uses computer numerical control (CNC) to control the machines used in the machining process. CNC m

Aluminum CNC processing is a popular choice for many manufacturing projects due to its cost-effective nature, ease of machining, and corrosion-resista

The raw metal or plastic material used for the part is just as important as how the part is machined; choosing the wrong material can add unnecessary

We had a lot of questions about the best way to fasten different 3D printed components. For example, when prototyping hardware products, it is often n

DEYUCNC specializes in high-precision small-volume and high-volume outsourcing processing, custom production and processing of CNC aluminum parts. In

There are many reasons for the deformation of aluminum alloy parts, which are related to the material, the shape of the part, the production condition

With the advancement of science and technology, the improvement of living standards, the diversification of product demand has become the norm. As far

CNC machining centers are widely used in the current machining market and will definitely become a trend in the future. For example, you can use alumi

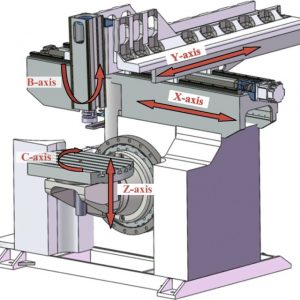

For moldmakers using multi-axis machines, developing CNC programs that take full advantage of these machine tools is a challenge. The goal is to make

The improvement of the accuracy of the rod-shaped tool has always been a difficult point in the manufacture of the tool. The main reason is that the e

If the precision CNC lathe fails, it should be stopped immediately, and diagnosed and eliminated in time. Otherwise, it will cause more damage and eve

CNC machining is the most important thing for enterprises to improve. This is also a big test for CNC lathes. Today, Jiang Zhou Hardware explains how

CNC parts processing manufacturers! It’s not that you don’t have machine maintenance, but you don’t have the right way! In CNC parts

CNC precision parts processing in the processing industry, pay attention to its accuracy, this is only a basic requirement, but also because of the hi

We provide CNC machining custom machining services for mechanical keyboard parts. Today, as electronic products become more and more abundant, most PC

Generally, mold part processors use the following methods: 1. Washing: Mainly milling the plane with a milling cutter. 2. Grinding: The grinding machi

CNC lathe processing is a high-tech processing method for machining precision metal parts. At present, there are many kinds of CNC lathes, which can b

Deep hole processing is known to be a difficult processing project. So why does deep hole machining reduce the diameter of the inner hole? cause The d