CNC Swiss

Machining Services

hold tighter tolerance bands over greater lengths.Our skilled CNC machinists

have years of experience providing the highest quality services to our customers

while exceeding industry standards of precision part manufacturing.

Precision CNC Swiss Machining For All Your Manufacturing Needs

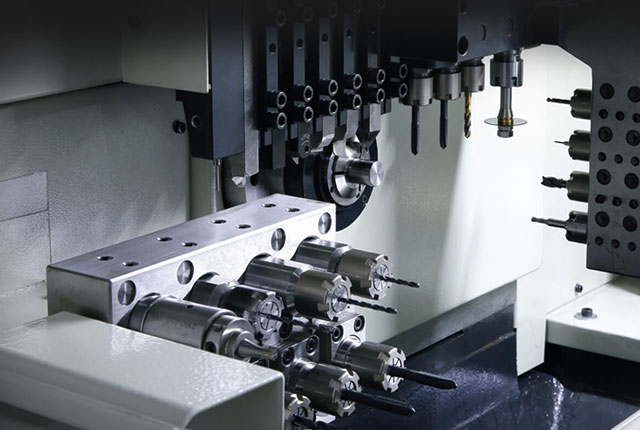

The professionals at DEYUCNC offer the latest in CNC Swiss machining technology to service a wide variety of industries all over the Europe and North America. If you need a complex component made by a manufacturer you can trust with ultra precision machining, the experts at DEYUCNC can do the job. Our skilled CNC machinists have years of experience providing the highest quality services to our customers while exceeding industry standards of precision part manufacturing.

Benefits of CNC Swiss Machining

What is Swiss CNC Machining?

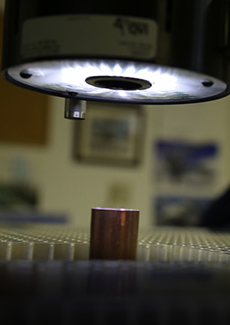

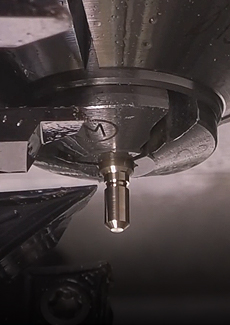

CNC Swiss machining is a type of precision manufacturing where parts are formed by CNC unit-operated lathes which rotate the part in a radial motion when cutting it. This type of specialized tool cutting allows the machine to perform several operations at once in a shorter amount of time.

DEYUCNC’ specific Swiss lathe turning applications center on micromachining in the 1mm to 4mm diameter range, as well as complex B-axis milling and eccentric applications up to 26mm in diameter.

Industries served by DEYUCNC

CNC Swiss machining is used across a number of industries to produce precision components with fast manufacturing times and repeatable accuracy

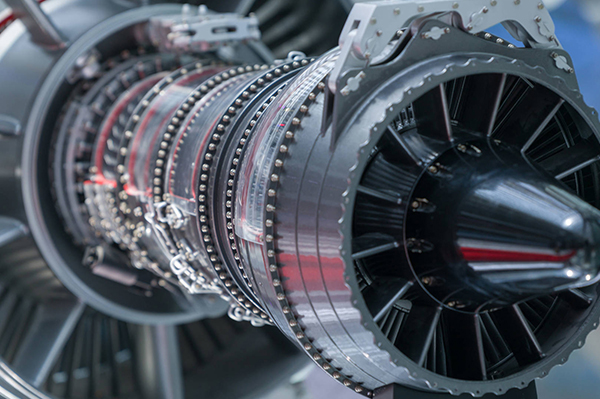

Aerospace

Aircraft and aerospace parts demand the highest precision and exacting accuracies. Depend on DEYUCNC to deliver components meeting or exceeding your quality standards.

Military/Defense

DEYUCNC not only provides unmatched 5 axis milling, wire EDM, and lathe services, but we keep the specifics of your components completely confidential, ensuring vital secrets are not leaked.

Aircraft

Our CNC professionals are capable of machining a multitude of aircraft components, and to the exact precision required when adhering to the highest industry standards.

Medical

Medical manufacturers and innovators alike choose DEYUCNC when they need to outsource CNC services, create prototypes, or simply cut costs while improving product quality.

Oil & Gas

When you need complex components for your oil & gas or energy applications, turn to DEYUCNC. From micromachining to 5 axis cnc milling, we can meet your every CNC need.

Optics

Microscopes, telescopes, cameras, and more requiring 100% accuracy on machined components will get nothing less than expected when DEYUCNC is on the job.

Swiss Cut Components for Your Industry

DEYUCNC provides high-quality CNC Swiss machining services to industries all over the world. Whether you work in the medical field or a company in the aerospace industry, you understand how important precision CNC parts are for particular systems. From CT scanners to robotic systems, and aircraft parts to couplers, properly-made precision parts are a necessity for many types of technological components to run.

Swiss CNC Machined Components for Medical Applications

- Catheters

- Ultrasound machines

- CT scanners

- Handheld surgical devices

- Litigation devices

- And much more

CNC Swiss Machining for Optical Components

Some of the CNC Swiss machined products needed in the optical industry include:

Some of the CNC Swiss machined products needed in the optical industry include:

- Microscopes

- Telescopes

- Cameras

- Glasses

- And much more

The Aerospace Industry Trusts DEYUCNC’ CNC Swiss Precision Parts

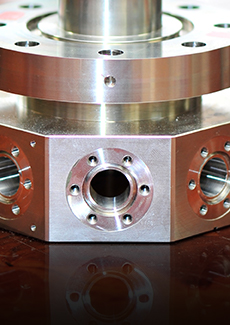

- Aerospace couplers

- Flanges

- Retainer rings

- Aircraft seat frames

- Guidance fins

- And much more

CNC Swiss Machining FAQ

Also called Swiss screw machining or Swiss style turning, Swiss machining refers to the process of turning parts in a radial motion with a CNC-operated lathe. Swiss lathes feed their stocks through a guide bushing. Like other types of CNC machining, CNC Swiss machining quickly and accurately produces small parts for a variety of industrial applications.

CNC Swiss machining is most often used to manufacture slender or delicate parts with tight tolerances. Since it uses 5 different axes, parts created by CNC Swiss machining are used by the aerospace, aviation, electronic, military and medical industries, to name just a few.

The term “CNC Swiss machining” is derived from CNC Swiss machining’s place of origin. Rudimentary Swiss screw machines were used by watchmakers in Switzerland to quickly produce large volumes of high-quality watches with small, complex parts, starting about 150 years ago. The U.S. started mass-producing Swiss screw machines during WWII, and the machines evolved into faster, higher-tech tools with CNC controls.

Swiss machines have less deflection and vibration, plus a short setup time. Their small size means less chip-to-chip time, which increases efficiency. Parts produced by Swiss machines are far more precise than their traditional counterparts, with an accuracy level up to 0.0002 inches. Some machines can also handle up to 20 tools in the tool zone.

CNC Swiss machining is commonly used to manufacture components for the medical, optical, tool & die, aerospace, food production, electronics and fuel industry. DEYUCNC has produced battery cores, couplers, flanges, retainer rings, seat frames and more for the aerospace industry. We’ve also produced catheters, ultrasound machines, surgical devices, CT scanners and other equipment for the medical field. Our optical contributions include parts for microscopes, cameras, telescopes and glasses. Food manufacturers have Swiss machined parts produced by DEYUCNC in their conveyor belts, motors, mixers, machines and more.

Need Assistance?

We are here for you! Call Us Today!

Send Orders to: mailto:sales@deyucnc.com