Precision CNC Components

for the Medical Industry

Precision Medical Components

DEYUCNC is a trusted supplier of medical components critical to surgical instruments, medical devices, and machines. Whether we’re engineering a Ventricle Assist Device (VAD) or a Lasik surgery blade, we ensure the highest tolerance and precision possible. DEYUCNC is committed to improving the quality of life for patients and medical staff throughout the industry.

DEYUCNC is a trusted supplier of medical components critical to surgical instruments, medical devices, and machines. Whether we’re engineering a Ventricle Assist Device (VAD) or a Lasik surgery blade, we ensure the highest tolerance and precision possible. DEYUCNC is committed to improving the quality of life for patients and medical staff throughout the industry.

Backed by many years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possible. Our experience and reputation have not gone unnoticed. We supply critical components to CT and MRI Scanner systems, as well as manufacture multiple types of surgical instruments, including Trocar/Cannula systems, biopsy cutters, and more. We also manufacture various medical components like Respiratory, Cardio Pulmonary, and Cardiac Devices. DEYUCNC is experienced in designing custom components for nearly every aspect of the Medical Industry.

Medical Machining Services Provided by DEYUCNC

Precision Guaranteed: Machining to the Highest Medical Industry Standards

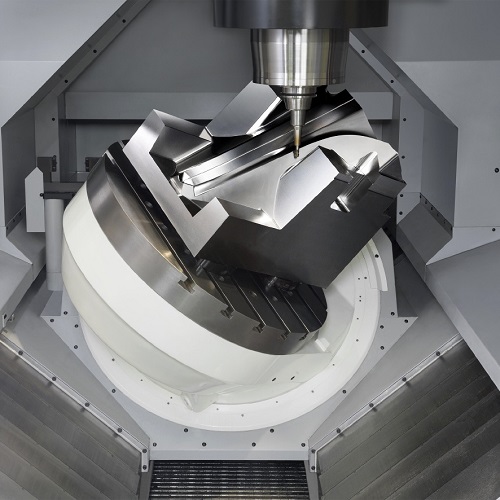

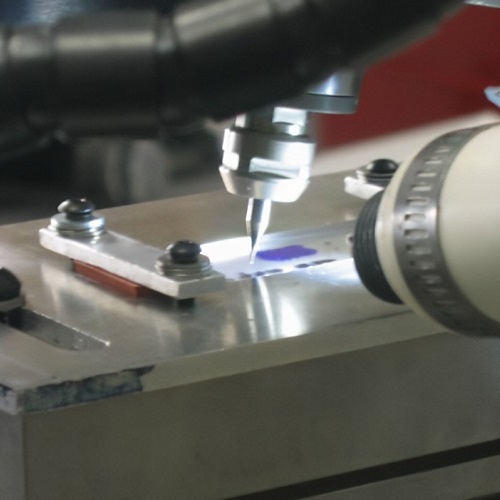

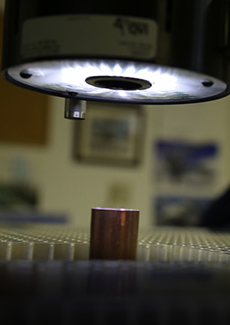

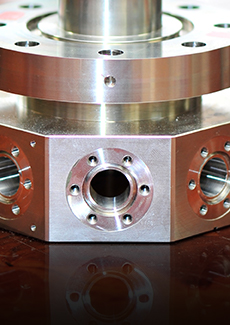

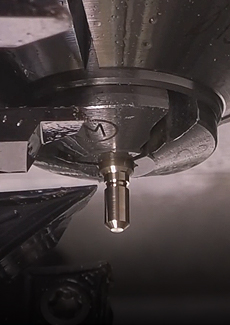

When it comes to medical machining, DEYUCNC is the answer. Excelling in the craft of 5 axis milling and electrical discharge machining, our engineers are a favorite among manufacturers of cardiovascular and orthopedic devices, surgical instrumentation, and implants. Miniature parts vital to the operation of dental equipment and tools are no challenge for our micromachining experts either. We work with materials ranging from titanium and stainless steel to invar, Kovar, and Inconnel. Whether you outsource the EDM machining of medical screws, need precision lathe work for an implant prototype, or require custom dies and molds to complete the job in-house, DEYUCNC will deliver as promised.

Many factors affect the results of a medical procedure. The same can be said for medical CNC machining. Our facility is temperature and dust controlled to assure the perfect environment for each process being performed, guaranteeing high precision results. We believe that an optimal environment creates optimal parts; it also allows us to achieve the tightest tolerances.

Surgical Device Parts Machined to the Highest Precision For Exacting Application Results

When we engineered a Lasik surgery tool for the medical industry we had to create a component precise enough to cut the lens of an eye without damaging the eye itself. Thanks to our 5 axis cnc milling and micromachining capabilities, we were able to create several tiny components operating exactly as required once assembled – exceeding our client’s expectations and ensuring a safe, reliable medical device. DEYUCNC can ensure the greatest precision and meet the highest standards of the medical industry –creating critical components used within the medical industry worldwide.

DEYUCNC is the right choice for CNC machining of medical parts including:

- Surgical scissors – an essential instrument in virtually every medical procedure, when they’re not used to get into skin they are used to cut sutures. Surgical scissors are available in a number of shapes and sizes to fit the need of a wide range of applications – they are particularly small when used in eye surgeries. If you’re a surgical instrument manufacturer looking for a reliable CNC machine shop that can achieve incredible results, DEYUCNC is the answer! Stainless steel, straight, curved, flat, blunt, sharp – whatever the specifications of your scissors, we can meet your exact demands.

- Cannulas – medical products like IV cannulas are in high demand because they’re used in virtually every medical center across the world. Like many surgical instruments, they are available in multiple sizes, similar to needle gauges. We use state-of-the-art equipment like multi-axis milling and wire EDM to produce high precision cannulas that are safe and effective. The hollow metal tube and sharp, angled point of an IV cannula can be produced with exacting accuracies in our DEYUCNC Machine Shop.

- Biopsy tubes – what is being biopsied determines the type of biopsy needle used during the procedure. Since not all biopsies are the same, there is no one size fits all needle for the task. We understand that safety, accuracy, and cost are all important factors when manufacturing medical tools; we help you win on all fronts with high quality, ultra-precision CNC machining services.

- Saw guides for bone surgery – helps orthopedic surgeons make the cleanest cuts possible, and protects against cutting too far into bone while sawing. Orthopedic procedures require the highest precision machined tools to produce the highest precision results. Whether you’re looking to outsource your medical machining needs permanently or require a custom saw guide for a future surgery, give us a call for a quote!

DEYUCNC can manufacture components for medical equipment with the specialized CNC Swiss machining lathes at our Shenzhen facility. We fabricate a wide variety of medical equipment components with CNC Swiss machining, including graspers, litigation devices, handheld surgical equipment, and catheters. Whether you need parts from 5-axis milling, wire EDM, micromachining or precision manufacturing, the specialized machining capabilities of our CNC Swiss machining lathes offer the very best in medical manufacturing services.

Our facility is perfectly controlled to guarantee high precision results, and we can ensure your medical component will be made with the highest accuracy and tightest controls. We also use the highest quality materials for EDM machining to ensure your medical part is sterile and guaranteed not to break when used in medical procedures. Some of the versatile, lightweight materials we use include:

- Titanium

- Stainless steel

- Invar

- Kovar

- Inconel

You don’t have to count on second-rate CNC machine shops to build your medical components – DEYUCNC is the way to go for all your Swiss lathe manufacturing needs. Learn more about our CNC Swiss machines at our DEYUCNC facility.

DEYUCNC is a flourishing micromachining company that extends its services to numerous branches of the medical industry, from medical part manufacturers to innovative prototype developers – and everything in between in need of high precision components to complete their applications. The medical industry counts on us for expertise, quality, and attention to detail. We use state-of-the-art technology, unavailable to other precision CNC shops, on the parts machined in our temperature controlled facility. Our variety of medical machining services promise measurable results.

- Collimators for CT scanners

- MRI table components

- Anodes for X-Ray systems

- Miniature components and gears for Cardiac Devices

- Insertion Equipment used in DNA analysis

- Implantable medical device components

- 5 axis machining of titanium implants for orthopedic use

- And so much more