Home » CNC Milling Parts » Machined Engine Titanium Connecting Rod Parts

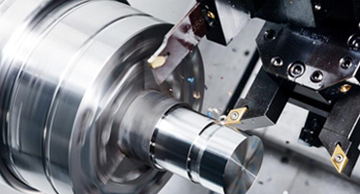

Machined Engine Titanium Connecting Rod Parts

| Custom CNC Machining Parts of Most Materials | |

| Quotation | According To Your Drawings (Size, Material, Thickness, Processing Content And Required Technology, etc.) |

| Tolerance / Surface Roughness | +/-0.005 – 0.01mm / Ra0.2 – Ra3.2(Customize Available) |

| Materials Available | Aluminum, Copper, Brass, Stainless Steel, Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE etc. |

| Surface Treatment | Polishing, General / Hard / Color Oxidation, Surface Chamfering, Tempering, etc. |

| Processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Testing Equipment | CMM / Tool Microscope / Multi-joint Arm / Automatic Height Gauge / Manual Height Gauge / Dial Gauge / Roughness Measurement. |

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages | 1.) 24 Hours Online Service & Quickly Quote / Delivery. 2.) 100% QC Quality Inspection Before Delivery, And Can Provide Quality Inspection Form. 3.) Rich CNC Machining Experience In the CNC Machining Area And Have A Senior Design Team To Offer Perfect Modification Suggestions. |

Get A Free Quotation >>> Go | |

WHY CHOOSE US?

We have advanced equipment and a manufacturing team consist of experienced workers, they guarantee the quality of the product.

Our after-sales service team is always stand by to help you any problem, we can serve you in 7/24 hours.

We provide customized processing services for customers, we will realize you idea.

Since we have our own factory, we can give you a most satisfactory price.

Our services

Our Manufacturing Capability

CNC Milling Processing

1.production machine:CNC Machining Center,CNC Engraving Machine,CNC Drilling Center(3 axis,4 axis,5 axis)

2.tolerance:+/-0.005mm

3.surface roughness:Ra 0.4

CNC Turning Processing

1.production machine: CNC turning lathe, automatic lathe, turing-milling mache

2.tolerance: +/-0.005mm

3.surface roughness:Ra 0.4

Wire EDM Cutting Processing

1.production machine: WEDM-LS, WEDM-HS

2.tolerance: +/-0.003mm

3.surface roughness:Ra 0.1

Company Profile

DEYUCNC is an entity enterprise integrating industry and trade and developing online and offline. We specialize in developing precision components, The business includes the processing of various special-shaped parts and models,CNC machining parts,CNC milling,Aluminum alloy, hard oxide, and other customized manufacturing parts.

While located in Shenzhen,Guangdong, China, our Machine Shop caters to the CNC needs of industries across the all around the world From medical devices to aircraft parts and any component in between, DEYUCNC can meet your needs no matter how complex.

Offering 3-axis,4-axis, and 5-axis milling, sinker EDM, wire EDM, and CNC lathe work, your guaranteed high precision results when you choose DEYUCNC. Our temperature and dust controlled facility creates the most ideal machining environment to ensure your exact specifications are met.

How to Order

1. Get part drawing or sample. (All the drawing are for quoting usage only, will not release to third party without written permission)

2. Quote with different quantities.

3. Ship sample before mass production.

4. Confirm order after sample gets approved.

Payment Method

Our company has several bank of American accounts. We also receive checks and bank transfer. 30% deposit in advance after sample is confirmed, 70% balance before shipping.

Minimum Quantity

There is no minimum order quantity. We quote and ship 1 piece if required by customer. We have quoted tremendous amount of order with total price including shipping below 100 US dollars.

Lead Time

Lead time: Vary greatly on each order, normally 15-20 day for an order that less than 500 pieces. For an order less than 50 pieces and weight less than 100 pounds, we choose international priority shipping service, total delivery time would be about 10 business days.

Material

Materials we are dealing with includes butnot limited to carbon steel, brass, aluminium, stainless steel and many kinds of plastic.

Service

DEYU specializes in prototyping, machining, sheet metal forming, surface treatment, metal electroplating, plastic injection molding and gear forming. We are also providing assembling, welding and painting service.

Shipping Status

Our shipping and packing department keeps our customers updated with the latest shipping status. Whenever your order is ready to pick up, you will receive a notification to remind you. If you have any questions about shipping or need help in tracking your order, please send an email with your order number to shipping@deyucnc.com