Ram/Sink/Plunge

EDM Services

Ram/Sink/Plunge EDM Services

Electrical Discharge Machining Producing Fine Detail and Intricate Shapes

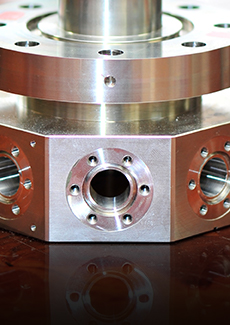

DEYUCNC specializes in Electrical Discharge Machining work, offering Ram/Sink/Plunge EDM services capable of producing fine detail/surface finish work, precision gears, and intricate cavities/shapes.

DEYUCNC specializes in Electrical Discharge Machining work, offering Ram/Sink/Plunge EDM services capable of producing fine detail/surface finish work, precision gears, and intricate cavities/shapes.

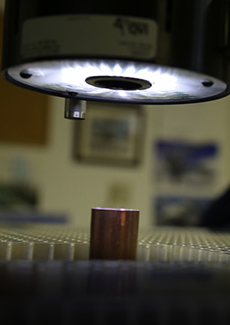

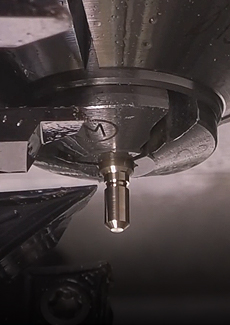

Sink EDM, Ram EDM, and Plunge EDM are one and the same. This EDM process uses custom machined electrodes (typically made from copper, graphite, or tungsten) which creates a spark between the material being machined and the electrode. The spark erodes materials in the EDM tools pathway, creating the complex cavities or shapes desired.

- Aluminum

- Brass

- Carbide

- Copper

- Hastelloy

- Inconel

- Kovar

- Stainless Steel

- Tool Steels

- Titanium

- Blind Cavities

- Intricate Details

- Sharp Corners

- Fine Surface Finishes

- Thin Walls

- Machining threads into hardened parts

- Blind Keyways

- Internal Splines,

- Squares, and Hexes

- Tolerances can be held to .0001”

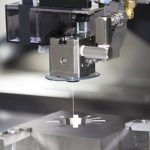

Sinker EDM and Wire EDM both produce a spark using an electrode to cut or erode the material being machined. In both processes, the spark created by the electrode never comes into physical contact with the machined part, maintaining the integrity of the material being cut and resulting in a burr-free finish. The difference between Sinker EDM and Wire EDM lies greatly in the type of electrode used in each process, the fact that no pre-drilled hole is required with Sinker EDM, as well as the 3D capacities the Sinker EDM is capable of achieving (Wire EDM only has the capabilities to produce 2D parts). Sinker EDM can produce parts that Wire EDM cannot – components that do not need to be cut all the way through.

AerospaceIndustries Commonly Utilizing Sink/Ram/Plunge EDM:

- Medical

- Tool and Die

- Automotive

- Military/Defense

The growth of the medical industry has no end in sight. As the population grows and technology advances more and more medical products are put on the market; with new innovations being created every day. Product engineers and manufacturers need an EDM Shop they can trust. The majority of our clients experience reduced costs when switching to DEYUCNC – our state-of-the-art equipment allows our CNC programmers to get medical parts machined in less time with more accuracy, reducing the number of bad parts. Whether your surgical component requires micron tolerances, fine surface finishes, thin walls, or any intricacy in between, we will deliver as expected.

Please note that DEYUCNC is not a gear house. We do not manufacture “normal” gears. We machine only small gears which need accuracies of a few microns. If tolerances for your gears are more than 30 microns, or if the size of your gear is larger than a few inches, we would not be a good fit.

The required patterns, fixtures, and blanks used to produce precision gears are all manufactured in-house at DEYUCNC, using our precision calibrated 5 Axis CNC Machining Centers and Super Precision Lathes. It is this complete in-house control over all of the required CNC machining processes which allow us to manufacture gears with such extreme precision. Our commitment to ultra-precision gear work limits our gear sizes to be small.

DEYUCNC has a long history of producing precision gears. We have manufactured AGMA Class 11 gears for the medical industry. Class 11 gears have tolerances in the range of +/- 0.0003” on the pitch diameter. We have also taken on projects for even more precise AGMA Class 12 gears that require 1-micron tolerance. In addition to these gears, we also have experience producing pinion gears and linear gear patterns with extreme accuracy. Typically, the material used for gears in the medical industry is 17-4 Precipitation Hardened Stainless Steel. We can certainly work with other alloys per your design requirements.e

Please note that DEYUCNC is not a gear house. We do not manufacture “normal” gears. We machine only small gears which need accuracies of a few microns. If tolerances for your gears are more than 30 microns, or if the size of your gear is larger than a few inches, we would not be a good fit.

The required patterns, fixtures, and blanks used to produce precision gears are all manufactured in-house at DEYUCNC, using our precision calibrated 5 Axis CNC Machining Centers and Super Precision Lathes. It is this complete in-house control over all of the required CNC machining processes which allow us to manufacture gears with such extreme precision. Our commitment to ultra-precision gear work limits our gear sizes to be small.

DEYUCNC has a long history of producing precision gears. We have manufactured AGMA Class 11 gears for the medical industry. Class 11 gears have tolerances in the range of +/- 0.0003” on the pitch diameter. We have also taken on projects for even more precise AGMA Class 12 gears that require 1-micron tolerance. In addition to these gears, we also have experience producing pinion gears and linear gear patterns with extreme accuracy. Typically, the material used for gears in the medical industry is 17-4 Precipitation Hardened Stainless Steel. We can certainly work with other alloys per your design requirements.e